Geological CO₂ storage take longer time than most expect

Moving swiftly is important, but moving with precision is crucial. When it comes to CO₂ storage, we need to do both. What is the best plan for success? An ongoing discussion within our team for years has revolved around the discrepancy between the general assumptions behind timelines.

The current timelines for de-risking potential CO₂ storage sites with the best appraisal strategy to narrow the estimated storage capacity ranges, often tend to be overly optimistic. Realistically, the process from advancing a site from the Lead or Prospect stage to operating status often spans between 5 to 8 years. However, in certain cases, there may be possibilities for accelerated advancement.

We have over the years had many discussions in our team revolving around timeline estimates used in the wider public before a CO₂ storage site reach the injection phase.

Proposed solutions from our subsurface experts

1 Enhanced awareness in the industry

Improved understanding within the CCS business regarding the uncertainties associated with geological CO₂ storage, the components an appraisal program usually consists of, associated costs, and establishing realistic timescales.

2 Common language

Facilitating a common communication framework to ensure comprehensive understanding among stakeholders engaged in geological CO₂ storage, regarding a project’s maturation process and confidence in the reliability of CO₂ storage capacity estimates.

3 Classification systems for communication of uncertainty and project maturity

For the latter, we are fortunate to have existing classification systems managing both uncertainty and maturity, consequently evaluating the feasibility of CO₂ storage projects. These long-standing systems have been used along with independent auditing used by banks, investors and publicly listed companies, and you can read about it in a new article coming soon.

In the following sections, we will focus on point 1 and 2.

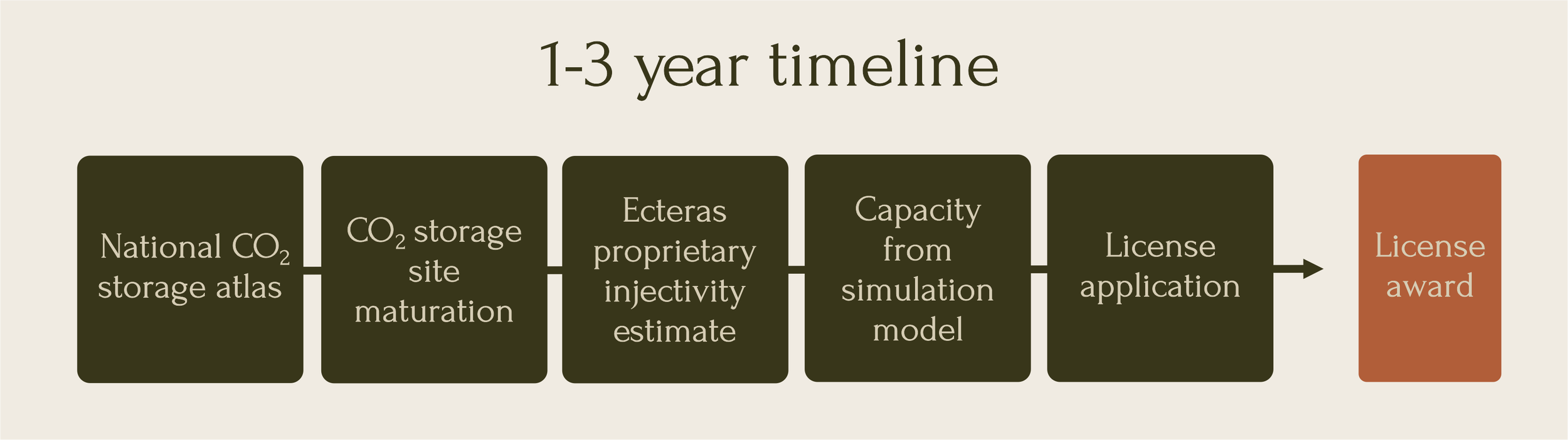

How long does it take to get a CO₂ storage license?

Provided that acreage is made available by countries for license applications, it often take years for the subsurface geologists to analyse the underground and find areas where there could possibly be potential for storing the CO₂. The quality of the analysis relies on the data availability and quality of the data. An example is that offshore Norway and UK there is high quality data available in most places where CO₂ storage could be considered, and onshore Europe is challenged in areas where there has not previously been exploration for coal, gas, oil or geothermal energy. An analysis require in-depth investigations and interpretation of existing data, where the geologists and reservoir engineers do their best to create scenarios for what the subsurface could be like. These scenarios are based on numerous assumptions and form the foundation of the initial business cases.

De-risking a potential CO₂ storage site through an appraisal program

When a license has been awarded, there is often a work program with a commitment to investigate further that has to be fulfilled. The timeline for this is often 3-5 years and involves several decisions in the license to ‘go ahead’ and invest more in investigations or moving the project ahead. Many licenses in Norway and Denmark have a commitment within the first year or two.

An example of a proposed appraisal program

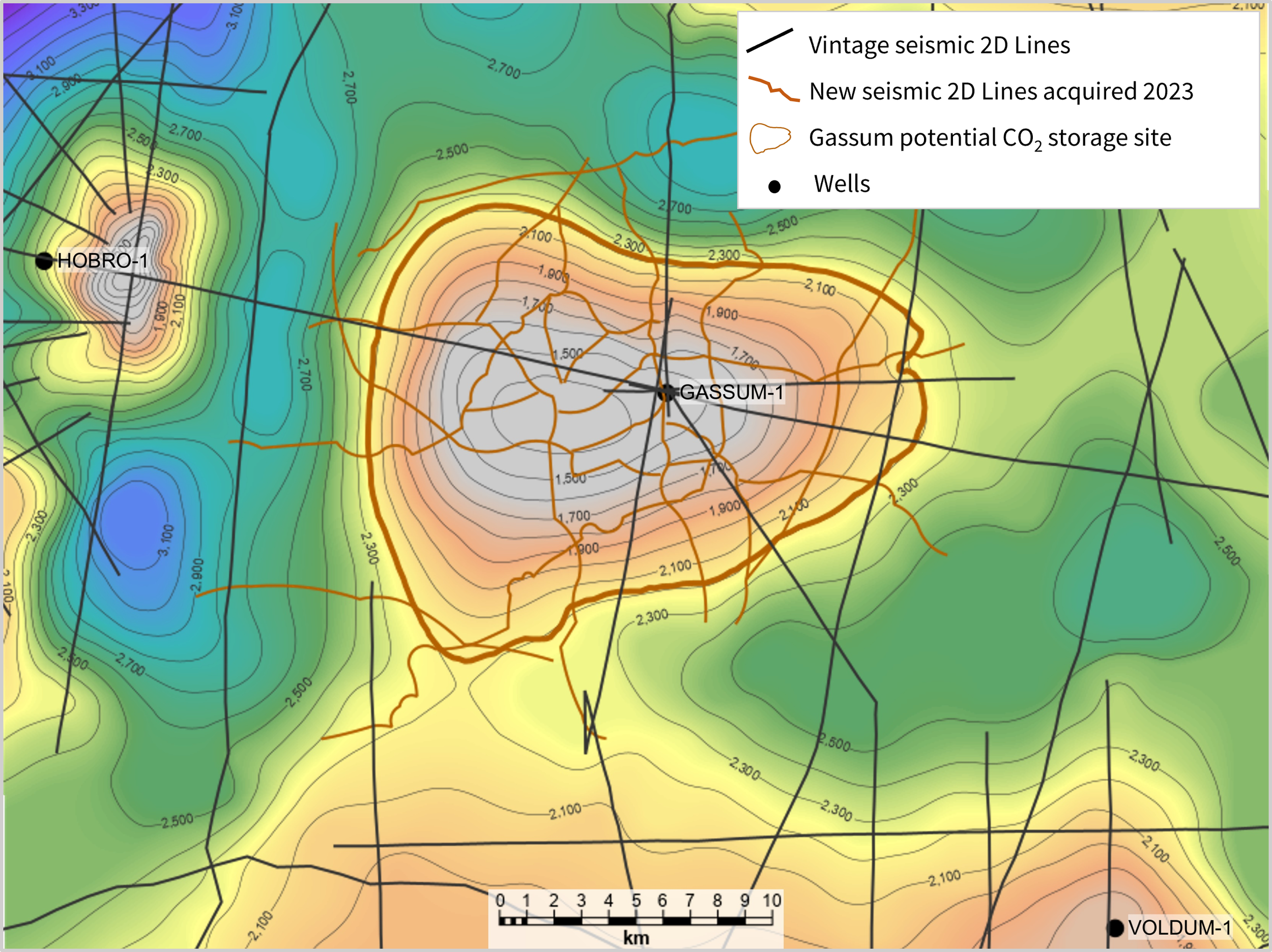

As an example for what it will take to mature a potential storage site onshore Denmark we are using the Gassum Site. It was included in the December 2023 license round, and an old map of the salt cored structure based on vintage seismic data is shown below.

Let us first describe what is known and what is uncertain in terms of data availability, and then explain what it takes to derisk the uncertainties.

Data available

For the map below, note that the vintage seismic lines that were available for the Gassum Site structure back in 2023 are marked in black, which is why the structure may change shape when the new seismic data is integrated. Those new 2D seismic lines have are shown in orange. Also note that the new seismic lines follow the roads in the area, which is a limiting factor when acquiring seismic data onshore in populated areas.

The Gassum-1 well was drilled shortly after the end of second world war, in the hunt for the gas that was back then discovered onshore in Germany. There were problems during drilling, why the Gamma Ray Log was acquired within the casing, thereby reducing the confidence of log interpretations significantly. Core data is available with core samples available to calibrate the uncertain log responses, but the storage capacity estimates are still associated with significant uncertainties and risk.

The map of the Ecteras Integrated 2023 Near Top Gassum Fm depth map illustrate that there is relatively low confidence on the geometry of the saddle point in the south, where the potential Voldum CO₂ storage site is located in close proximity to the geothermal project near Aarhus by Innargi.

How we would de-risk the potential CO₂ storage site

In order to reduce risk, our recommendation for an appraisal program would be as follows:

Acquire more regional scale 2D seismic data to understand the regional distribution of the reservoir and aquifer connectivity.

Acquire 3D seismic data that covers the entire structure, including a focus area of the saddle point to the south.

Update structure map and capacity estimate ranges with new reduced uncertainty.

Appraisal well near crest No. 1 to test reservoir presence and quality (keeper well for future injection?)

Drill Appraisal well No. 2 at flank of structure to test aquifer presence and quality.

Update geological model and simulation model to update the basis for economics in the business case.

Ensure delivery of CO₂ for injection at the right time to ensure revenue stream.

Final Investment Decision for developing site (FID), provided site is suitable for CO₂ injection and financing is secured.

To ensure safe drilling operations, a well often takes several years to plan, including tendering for and securing an offshore or onshore drilling rig, getting the required permits in place from specific authorities. An example of what is required in terms of application documents for the Northern Lights | Longship | Aurora project, located offshore, can be found here.

For wells that are planned for being in touch with CO₂, which is extremely corrosive, a special type of equipment is required. Many long leads items have one or two years waiting time. The first well on the Northern Lights project took three months to complete (and cost 1 billion NOK), and the second well took just one month to complete. Onshore wells can be drilled at a fraction of the cost, but environmental permits must be expected to take longer to get into place. It could easily be several years prior to securing the drilling permit unless special efforts are made to accelerate the process.

When the data from the well and seismic data are acquired and available, the geological models must be updated with the latest information, and the simulation of how the CO₂ and pressure moves in the reservoir and aquifer updated accordingly. With this in place, it is possible to evaluate the economical aspects of a business case with a relatively good confidence, and it is possible to reach a Final Investment Decision for the remaining part of the project.

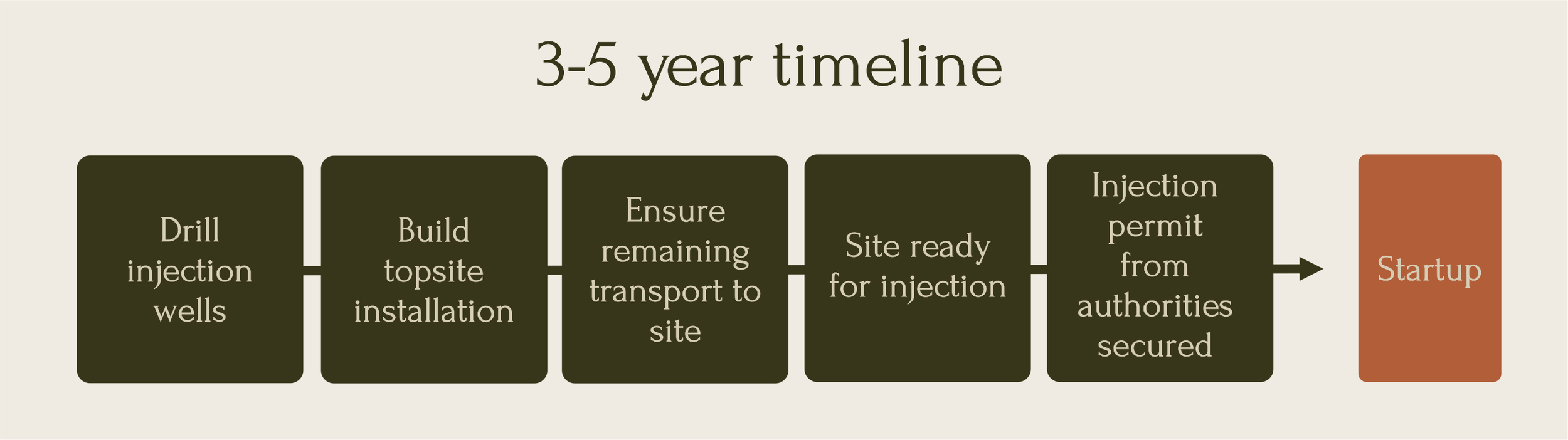

Next step: developing the CO₂ storage site

The development phase of an injection site is the most investment capital heavy part of the project. It involves well drilling, topside construction and installation and to get all the remaining pieces of the interconnected business value chain aligned. It requires close communication and collaboration between public and private partners to ensure efficient operations and avoid delays. Only when a permit is secured from the authorities injection can begin. Note that the European Commission will review each permit and provide feedback to the member states prior to any permits being approved in EU and EEA countries.

Our core message is this: With the timelines given above, there is a minimum of 7 years from the screening for a potential CO2 storage site begins, till a site is in operation. The worst case scenarios is 13 years. This is important to keep in mind for the different business cases in the CCS value chain, as any delays might impact the value stream in a negative way. Finding quality storage sites require detailed insights into a storage site appraisal and development, and it will enable ranking of this important perspective of the possibilities to select the best business opportunity.